The CJ series is mainly used for laser welding of aluminum alloy components of different types of air conditioner pipelines.

Model :

CJ2000Power supply :

380VStraight axis positioning accuracy :

0.1mm/mStraight axis re-positioning accuracy :

0.06mmLaser Power Option :

2000WY-axis travel :

350mmNumber of power phases :

3+N+PEZ-axis travel :

300mmFrequency :

50HzP-axis travel :

150mmB1-axis travel :

N*360°B2-axis travel :

N*360°Welding process :

Laser wire fill weldingWorkstation :

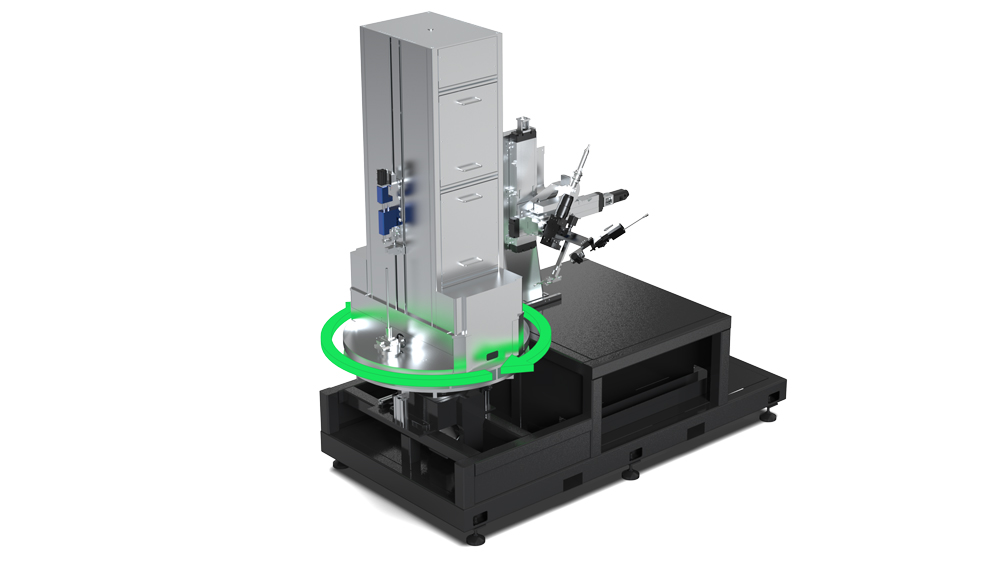

2CJ Series Laser Welding Machine

The CJ series laser welding machine is of one-to-N design, which can improve laser utilization. It is fully servo-driven and features high precision, enabling the welding of different connecting welds of air-conditioner pipelines. It is equipped with a complete set of Omron laser welding control system and has precise wire feeding function. The processing station has a compact structure and small floor area.

Feature

Dual Station Workbench

Equipped with a dual-station rotary workbench, the rotary driving mechanism is powered by a cam divider driven by a variable-frequency motor. The workbench features two servo motors and a rotating shaft driven by high-precision planetary reducers. The design of the rotating shaft incorporates considerations for workpiece sinking requirements, thereby enhancing the versatility of welding components.

Y/Z/P Axis Motion Module

For the linear motion axis, all transmission components are driven by high-dynamic-performance servo motors and are equipped with precision ball screws, high-precision linear guides, and other efficient transmission mechanisms, thereby ensuring precise and reliable transmission. The linear rail slider is fitted with a protective scraper to clean debris from the guide rails. The Y-axis track features an integral accordion-style protective cover to enhance its service life. The P-axis serves as a rotary axis for adjusting the angle of the welding head.

Compression System

To enhance adaptability to a wider range of products, a lifting and pressing system has been designed. The lifting mechanism employs a servo motor and ball screw to drive the tooling vertically, while the cylinder serves as the actuator for compression. Additionally, this device is equipped with multiple sensors to facilitate various detection functions:

1. A laser distance sensor is installed to measure the height of the part.

2. A laser sensor is used to monitor the status of workpiece support.

3. The maximum pressing height of the pressing system is 650 mm.

Cutting Sample

Certificate

Tags :