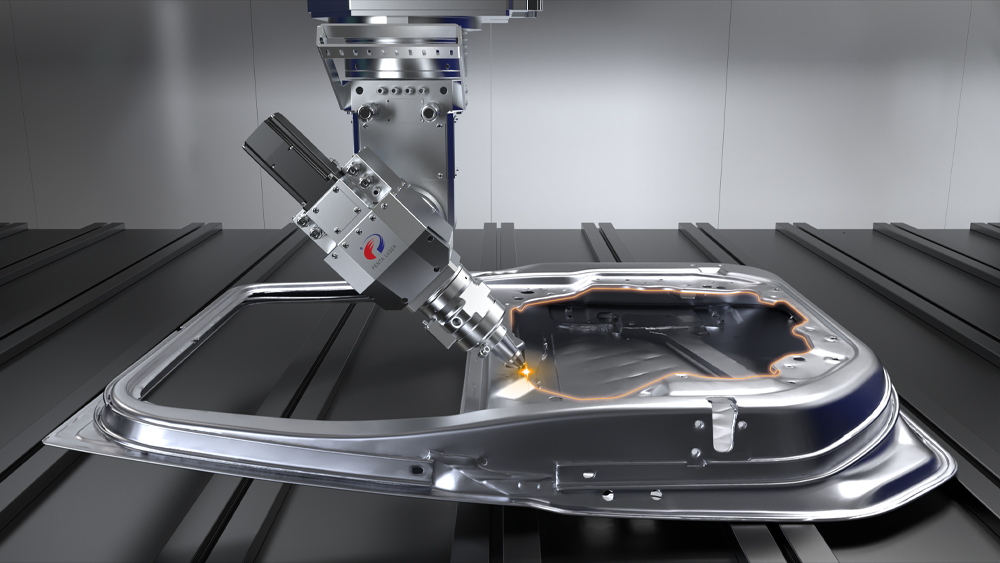

The GAN series is a 3D laser cutting machine specifically designed for cutting complex-shaped workpieces.

Model :

GAN3015/4020C-axis Rotation angle :

N×360°Straight axis positioning accuracy :

0.1mmStraight axis re-positioning accuracy :

0.06mmMaximum Acceleration :

1GMaximum speed of linear axis :

100m/minMaximum speed of axis of rotation :

90rpmRepetitive accuracy ofrotate axis position :

0.01°Laser Power Option :

1000-4000WOperating system :

Smart managerGAN Series 3D Laser Cutting Machine

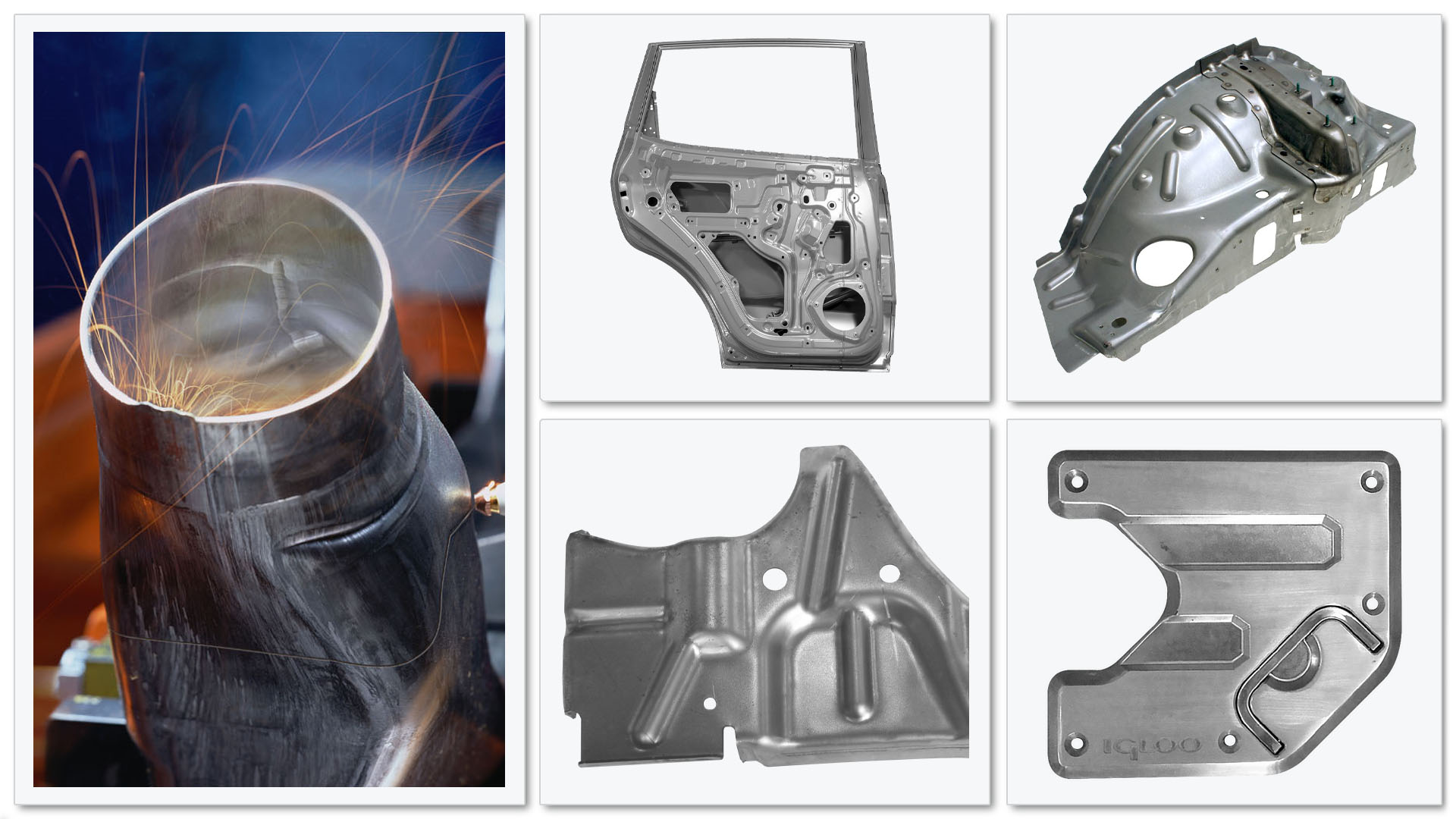

The GAN series 3D laser cutting machine is specifically designed for the precise cutting of various complex-shaped workpieces. It is capable of processing a wide range of metal materials, including steel, aluminum, and copper. This versatile equipment finds extensive application in industries such as automotive manufacturing, aerospace, electronics, and mold making, where it can be used for cutting body panels, components, molds, and decorative elements. The 3D five-axis laser cutting machine boasts high precision, high efficiency, and exceptional flexibility, enabling it to meet the stringent cutting requirements of intricate workpieces.

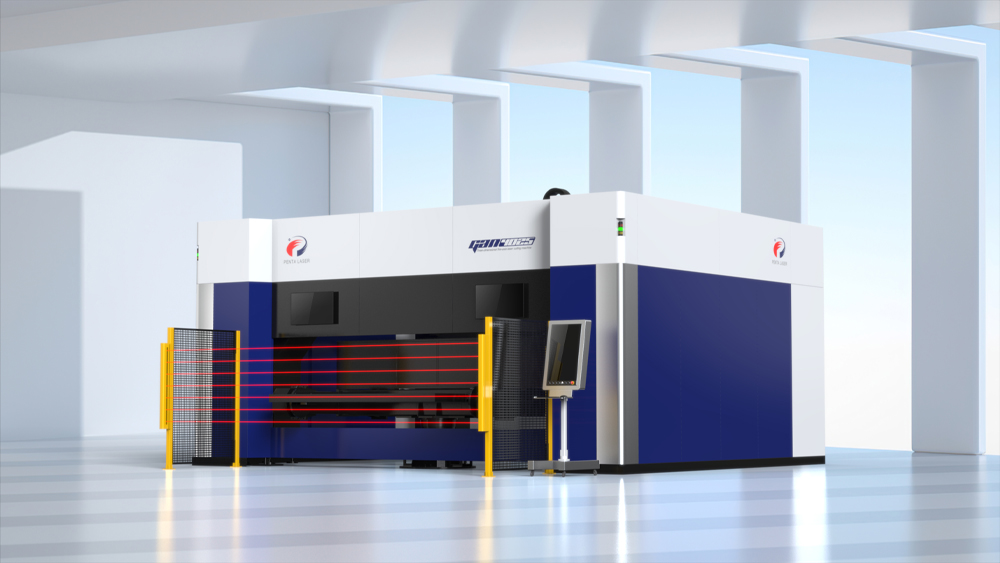

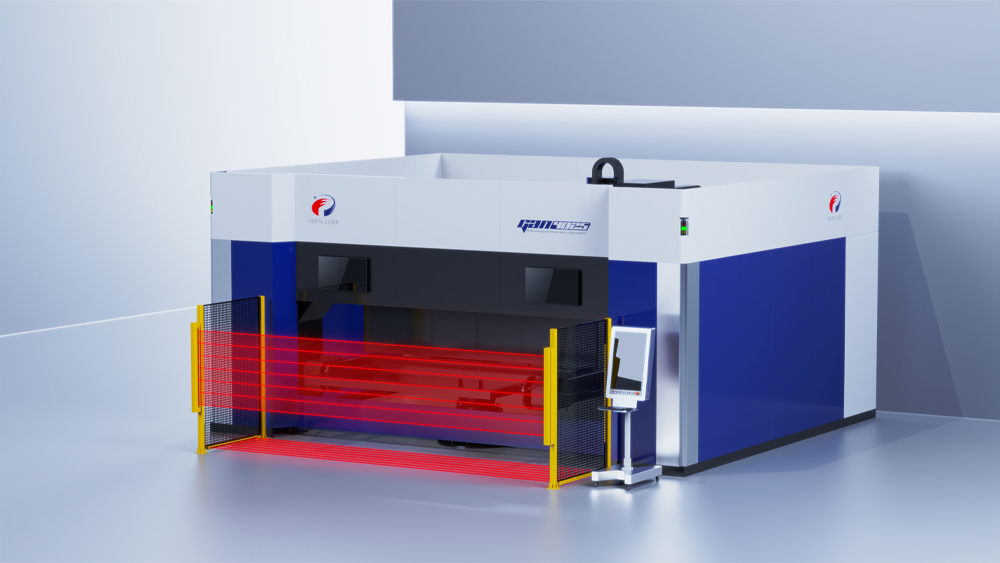

Safety Light Grating

The safety interlock protective door facilitates enclosed operations, while an intelligent safety light curtain prevents unauthorized personnel entry.

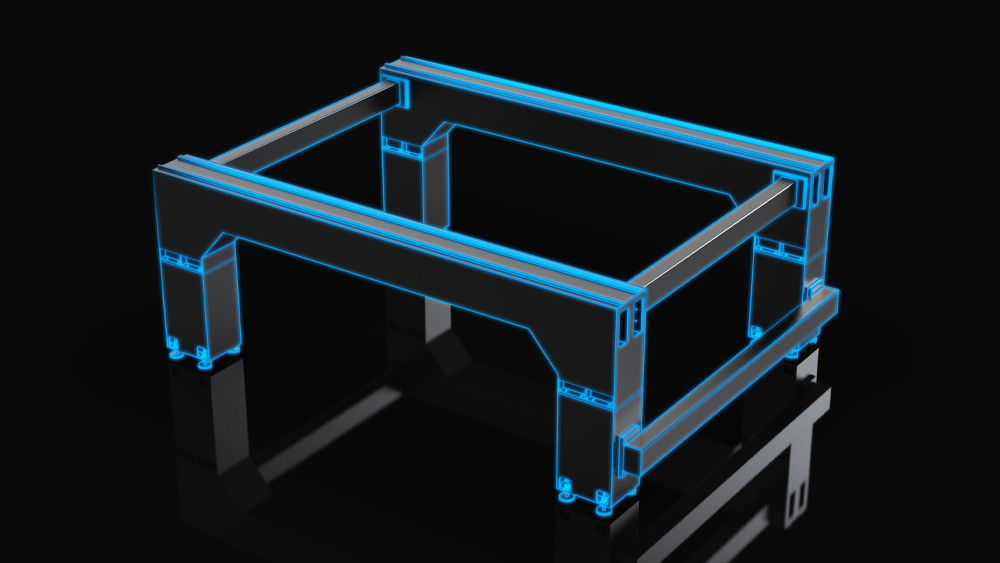

Dynamic Performance

The high-strength crossbeam and precision manufacturing process ensure optimal dynamic performance, accuracy, and stability of the machine during operation. The linear axis can achieve a maximum speed of 100 m/min and an acceleration of up to 1G.

Five-axis Linkage Cutting Head

The five-axis linkage cutting head can rotate at N*360° and swing at ±135°, smoothly transitioning between planes. This exceptional flexibility enables more precise and efficient cutting operations.

Operation Software

■The latest version of Smart Manager is a European-developed CNC software designed for seamless integration with Italian CNC systems. It features an advanced laser cutting database, enabling real-time adjustment of cutting parameters to achieve optimal cutting quality.

■The new algorithm enables faster response.

■The system supports configuration of up to 15 layers of cutting parameters and 25 layers of perforation methods.

Cutting Sample

Certificate

Tags :