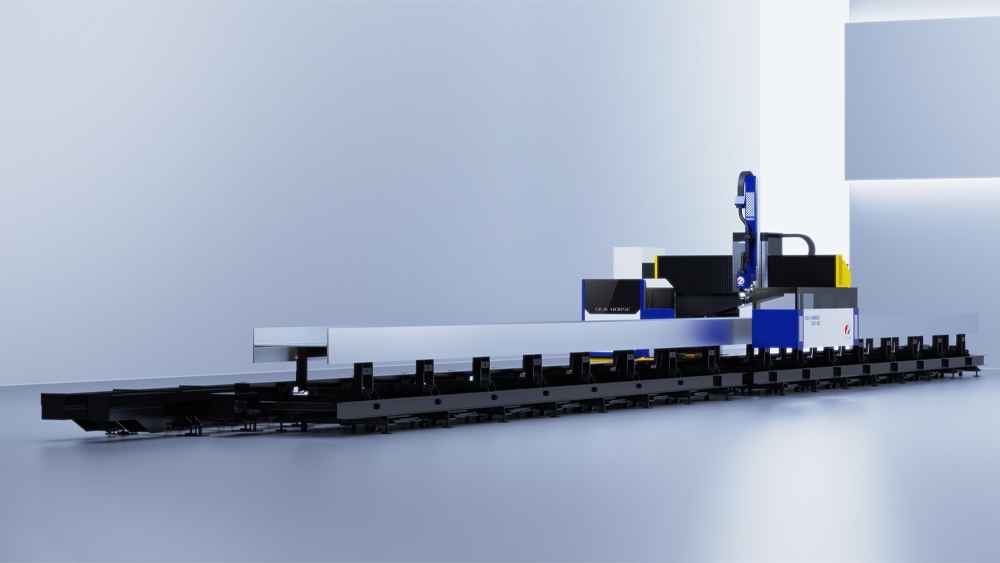

The SEA HORSE 26100 series is a powerful, easy-to-operate H-beam laser cutting machine, which can cut an H-beam with a maximum length of 26 meters.

Model :

Sea horse 26100Table Travel :

(200-1000)mm×260000mmB-axis Rotation angle :

±90°C-axis Rotation angle :

±45°Straight axis positioning accuracy :

±0.05mmStraight axis re-positioning accuracy :

±0.02mmRepetitive accuracy ofrotate axis position :

8arc minLaser Power Option :

2000-20000WOperating system :

Smart managerSea Horse 26100 H-Beam Laser Cutting Machine

The SEA HORSE 26100 series is a powerful and easy-to-operate H-beam laser cutting machine. It has the capability to process beams with a maximum length of 26 meters, which makes it especially suitable for the processing requirements of industries like construction, bridges, automotive, and shipbuilding. By using this machine, production efficiency can be significantly improved, costs can be reduced, and better cutting quality can be ensured. As a result, it possesses great market potential.

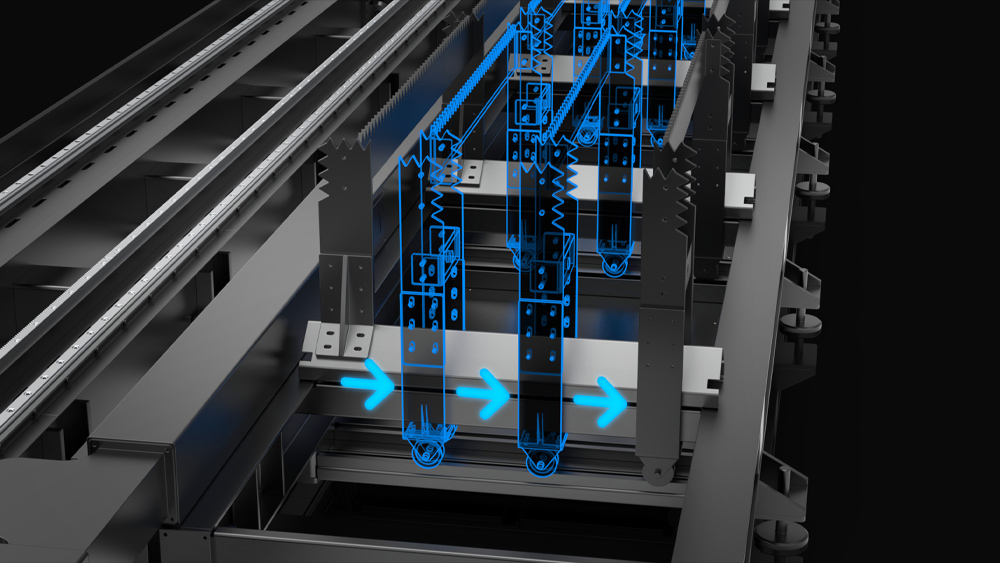

Dynamic Performance

The high-strength crossbeam and the precision manufacturing process ensure the dynamic performance, accuracy, and stability of the machine during its operation. The maximum speed of the linear axis can reach 45 meters per minute.

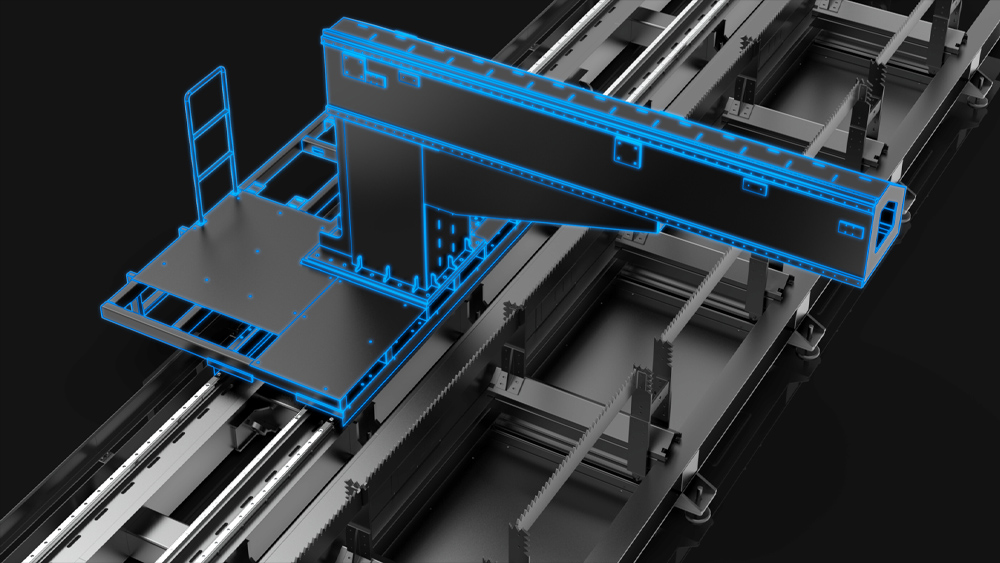

Move The Rack

The design of the rack movement is capable of meeting the processing requirements for widths that range from 400 to 1000 millimeters.

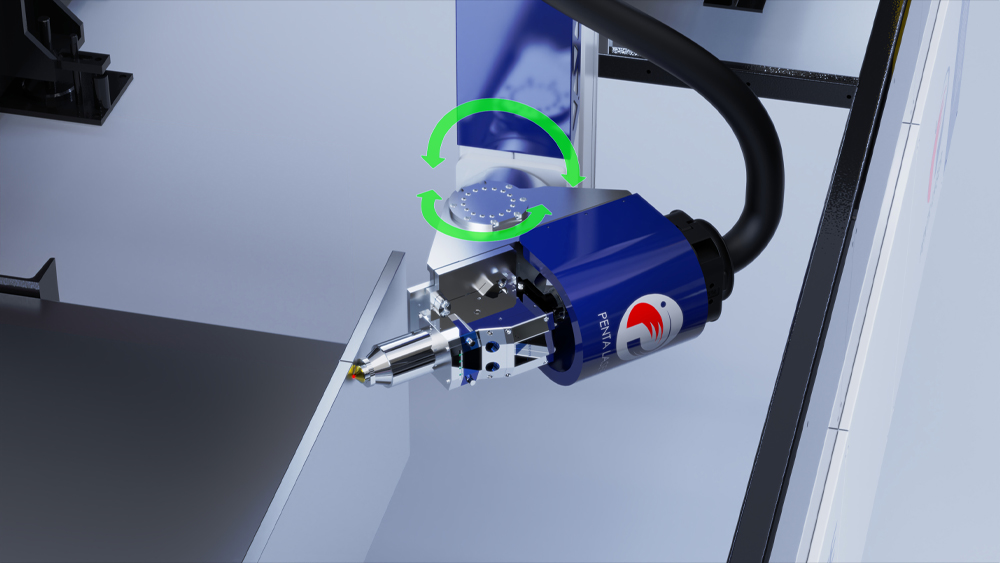

Bevel Cutting

The SEA HORSE H-beam laser cutting machine can achieve high-quality bevel cuts. The B axis can reach an angle range of up to ±90°, and the C axis can reach an angle range of up to ±45°.

Operation Software

■The latest version of Smart Manager is a European CNC software that can integrate with Italian CNC systems. Equipped with a powerful laser cutting database, it (the software) enables users to adjust the laser cutting parameters in real-time, thus achieving optimal cutting quality.

■The innovative algorithm significantly facilitates a much quicker response, enhancing overall operational efficiency.

■It allows for the setting of cutting parameters across 15 layers and the configuration of perforation methods for 25 layers.

Cutting Sample

Certificate

Tags :