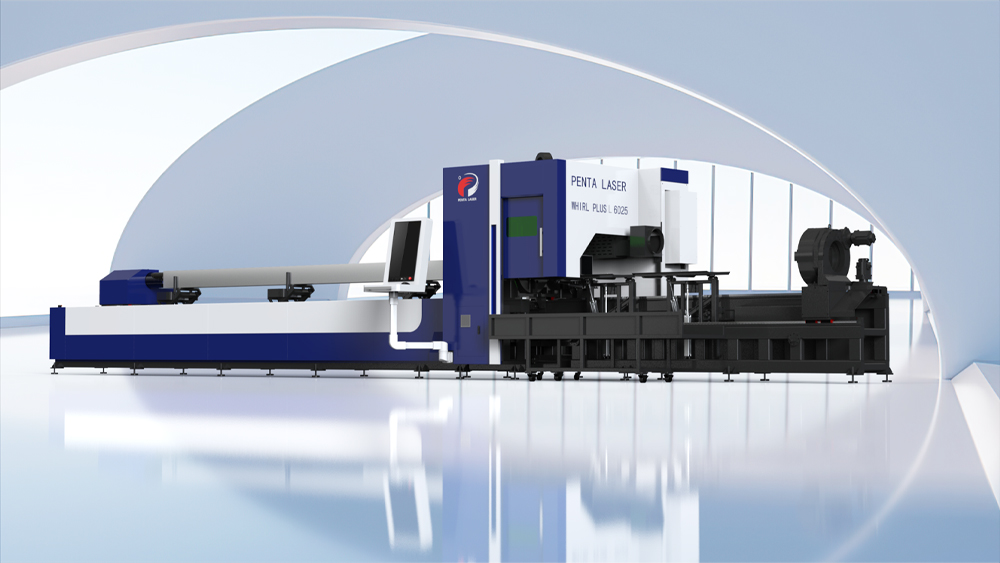

The WPL series is a cost-effective and efficient dedicated laser tube cutting machine.

Model :

WPL 6025/9025/9035/12035Table Travel :

6000mm-12000mmA/P axis rotates :

N×360°Repetitive accuracy oflinear axis position :

±0.03mmMaximum speed of linear axis :

90m/minMaximum speed of axis of rotation :

100rpmRepetitive accuracy ofrotate axis position :

±8arc minPipe diameter range :

Φ20-240mm □20×20-240×240mmMaximum processing capacity :

40kg/mBevel cutting :

YESLaser Power Option :

3000-6000WOperating system :

Smart managerWPL Series Laser Tube Cutting Machine

The WPL series laser tube cutting machine is a high-performance, efficient, and high-precision solution. The servo-supported loading system automatically adjusts the support height according to the programmed settings. The unloading system features a flat floating support, while the square hole chuck can securely clamp both square and round tubes with the same maximum diameter. During the cutting process, waste and finished products are automatically separated, thereby reducing the labor required for material handling.

Feature

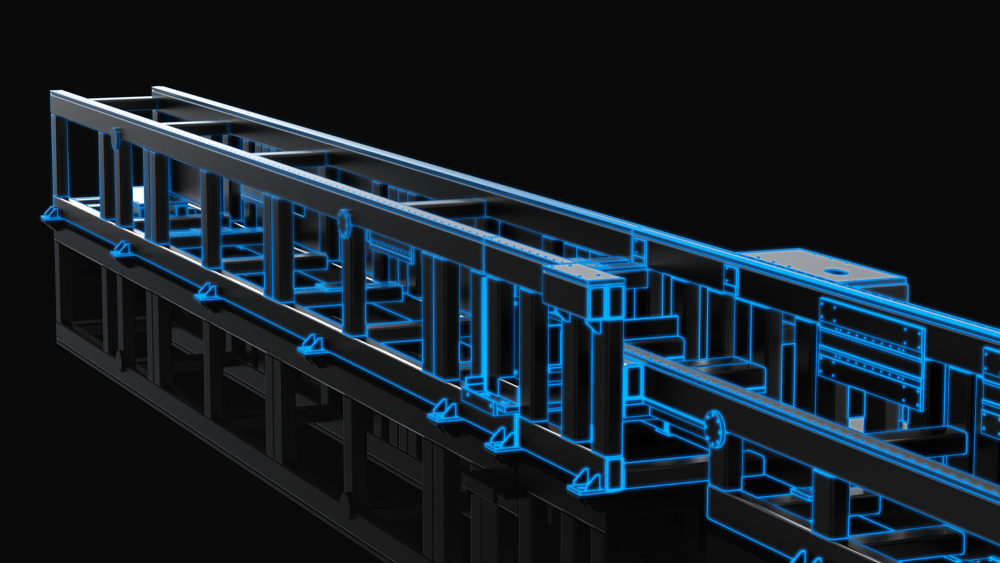

Dynamic Performance

The high-strength crossbeam and precision manufacturing process ensure optimal dynamic performance, accuracy, and stability during machine operation. The linear axis can achieve a maximum speed of 90 m/min, while the rotational axis can reach a maximum speed of 100 rpm.

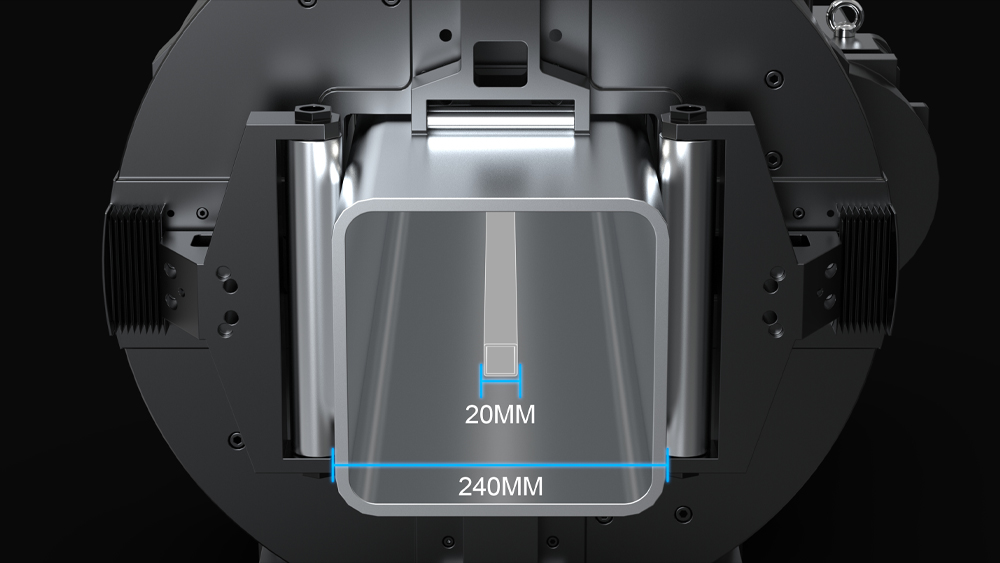

The Clamping Range of the Chuck

Using a square chuck, the maximum diameter for cutting both round and square tubes is identical. The diameter range for both types of tubes is from 20 mm to 240 mm.

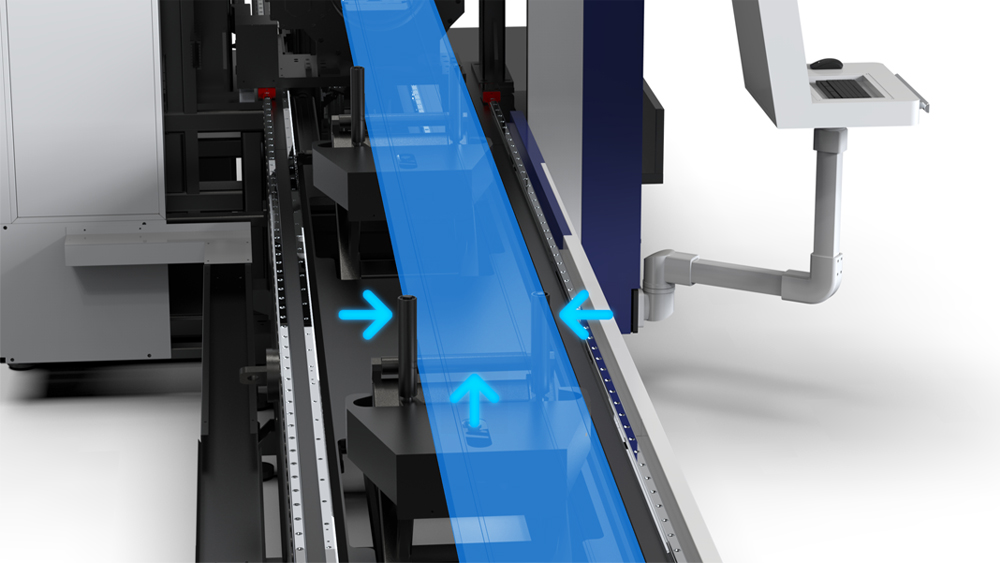

Servo Support With Buffer Cylinder

Both the loading and unloading ends are equipped with high-sensitivity, servo-driven active supports to ensure cutting stability and enhance accuracy.

Operation Software

■The latest version of Smart Manager is a European-developed CNC software designed for seamless integration with Italian CNC systems. It features an advanced laser cutting database, enabling real-time adjustment of cutting parameters to achieve optimal cutting quality.

■The new algorithm enables faster response.

■The system supports configuration of up to 15 layers of cutting parameters and 25 layers of perforation methods.

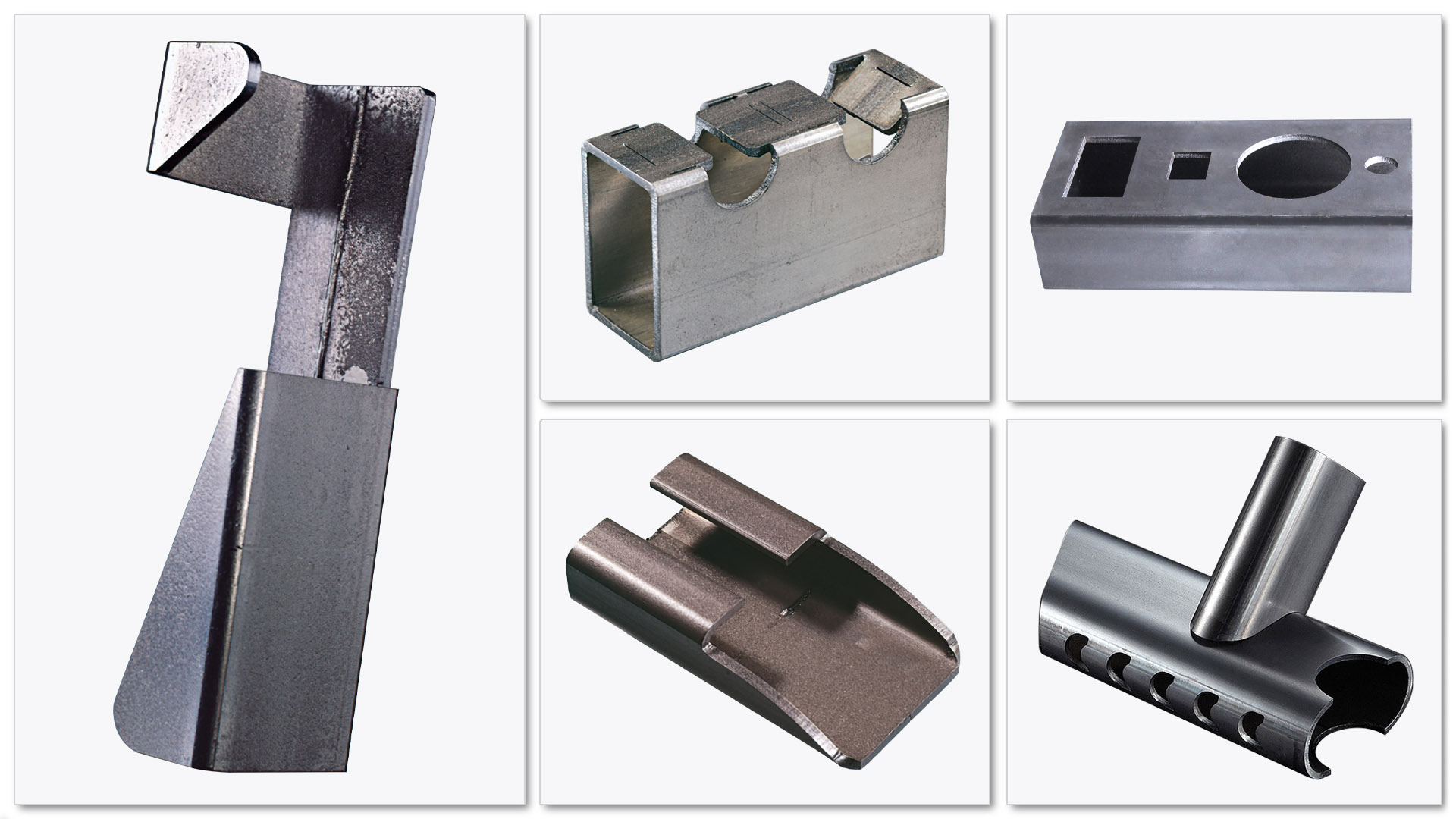

Cutting Sample

Certificate

Tags :