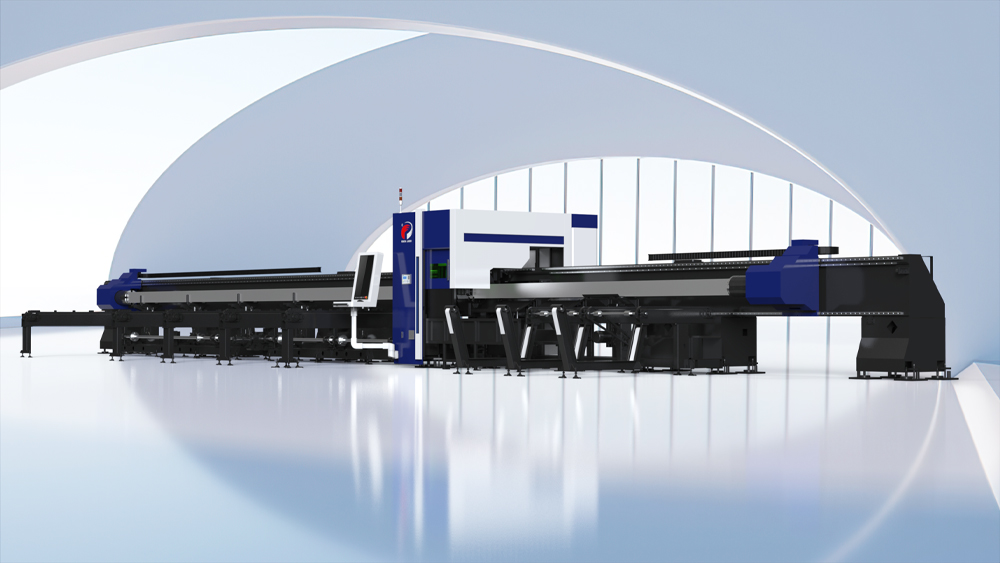

The WPC series can easily cut large diameter tubes, heavy-duty tubes, and extremely long tubes.

Model :

WP9036C/12036CTable Travel :

9000-12000mmA/P axis rotates :

N×360°Repetitive accuracy oflinear axis position :

±0.03mmMaximum speed of linear axis :

72m/minMaximum speed of axis of rotation :

75rpmRepetitive accuracy ofrotate axis position :

±8arc minPipe diameter range :

Φ20-350mm □20×20-350×350mmMaximum processing capacity :

100kg/mBevel cutting :

OptionalLaser Power Option :

3000-6000WOperating system :

Smart managerWPC Series Laser Tube Cutting Machine

The WPC series laser tube cutting machine is specifically designed for heavy-duty tube cutting applications. It features a customized large-mouth, high-load-bearing side-hanging chuck with a maximum load capacity of 1.2 tons. The machine comes standard with a semi-automatic loading system, which includes a large-clamping-force fixture to ensure precise tube centering during loading. The loading side is supported by a servo-controlled floating supporter, while the unloading side utilizes a servo-controlled flat floating supporter. An optional bevel cutting function is also available.

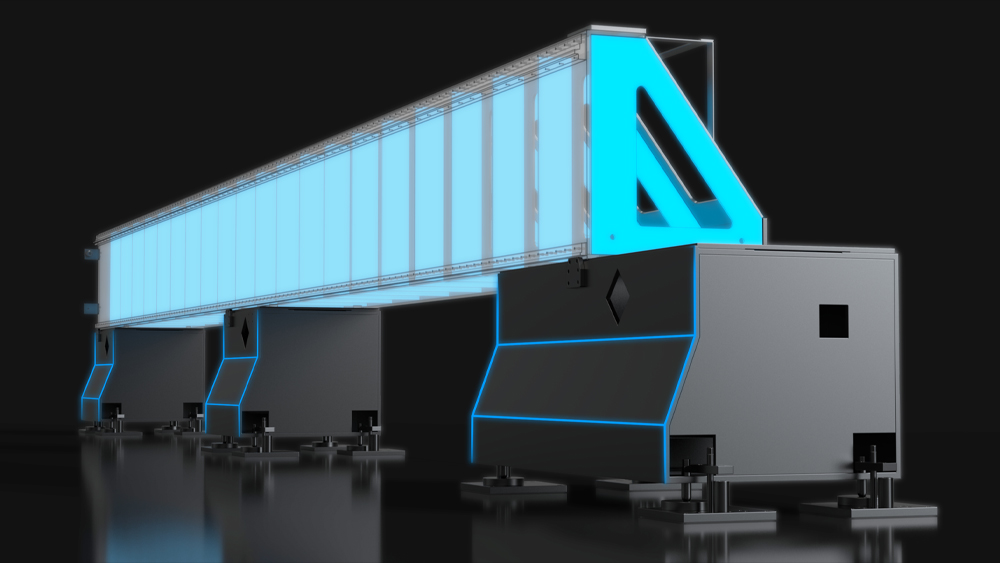

Dynamic Performance

The high-strength crossbeam and precision manufacturing process ensure optimal dynamic performance, accuracy, and stability during machine operation. The maximum linear axis speed can reach 72 m/min, while the maximum rotational axis speed can reach 75 rpm.

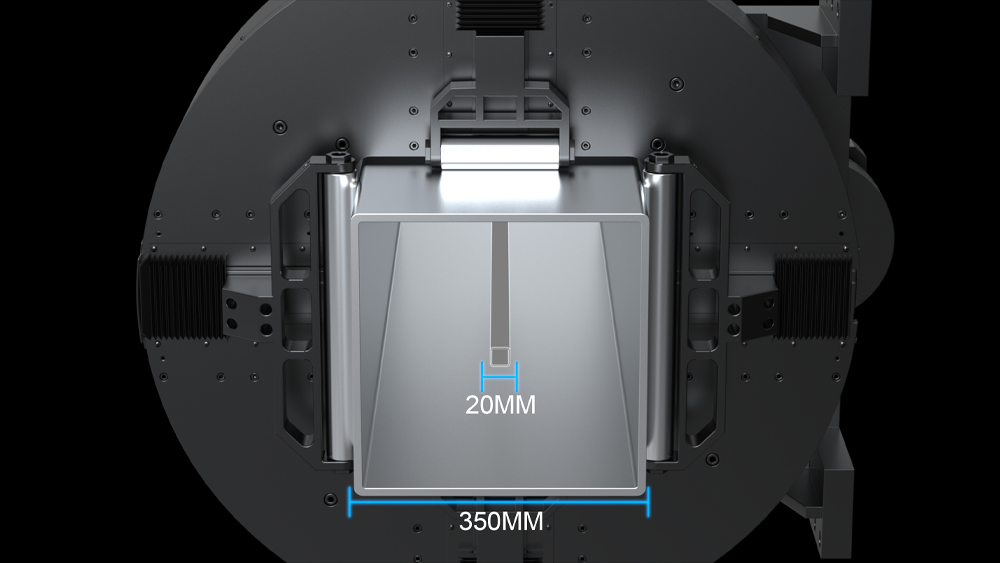

The Clamping Range Of The Chuck

Using a square chuck, the maximum diameter for cutting round tubes is equal to the maximum diameter for cutting square tubes.The diameter ranges from 20mm to 350mm.

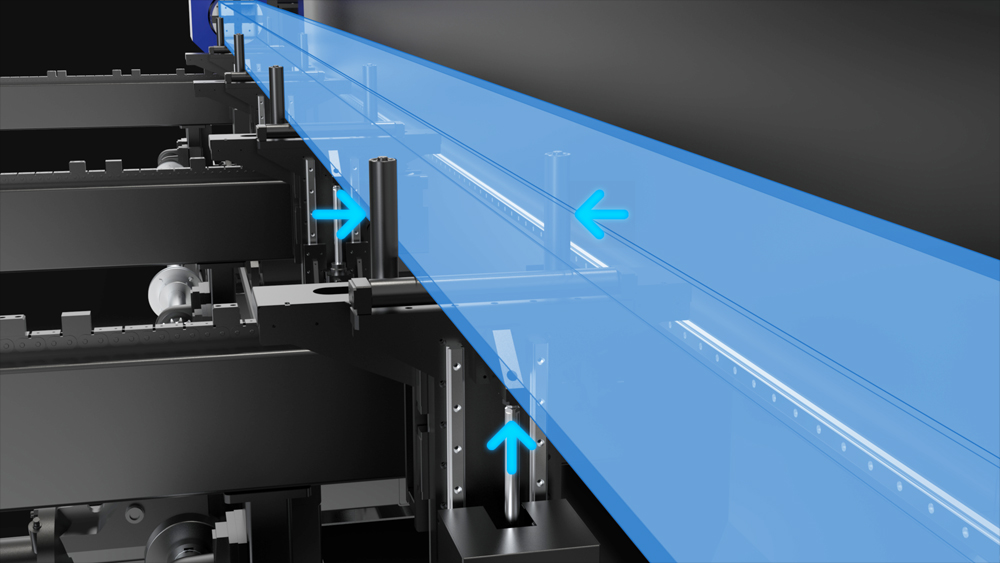

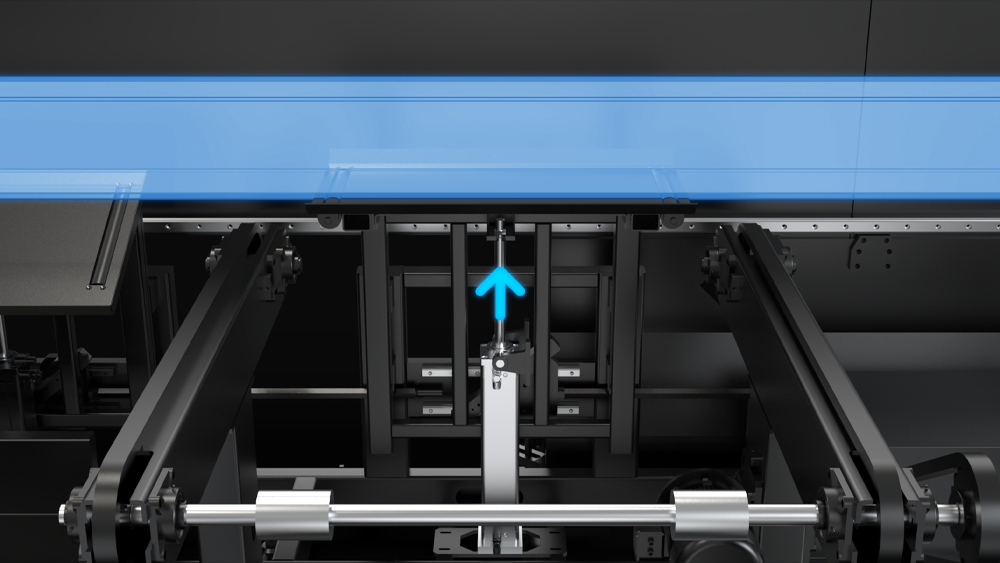

Servo Support With Buffer Cylinder

Both the loading side and the unloading side are equipped with high-sensitivity servo-driven active support to ensure the stability of tube cutting and improve cutting accuracy.

Operation Software

■The latest version of Smart Manager is a European-developed CNC software designed for seamless integration with Italian CNC systems. It features an advanced laser cutting database, enabling real-time adjustment of cutting parameters to achieve optimal cutting quality.

■The new algorithm enables faster response.

■The system supports configuration of up to 15 layers of cutting parameters and 25 layers of perforation methods.

Cutting Sample

Certificate

Tags :